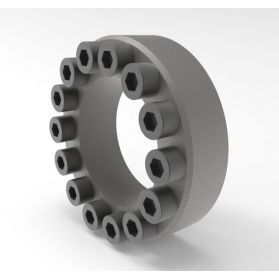

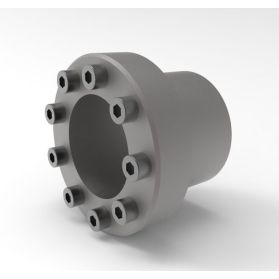

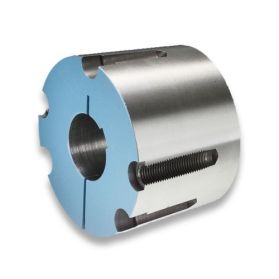

Clamping elements and shaft-hub connections

Perfectly matching shaft locking devices for optimal efficiency

Angst+Pfister's shaft locking devices create a backlash-free connection with high concentricity at the interface between the shaft (driving motor shaft and driven output shaft) and pulley (timing belt or V-belt pulley). Due to the additional machine element, the torque-generating and torque-absorbing components can be protected from destruction by the so-called deflection.

Assemblies and machine elements that are in direct functional interaction with each other have in well-balanced constructions reasonable orders of magnitude in relation to each other. This is also the case with belt drives. When optimally dimensioned, they are in a certain size relationship to the surrounding structure and its individual parts.

An optimal selection of drive components – taking into account the service life – can never be made across the board, but always results from the individual requirements of the respective application and industry. If the shaft-hub connection is selected in a specified manner and perfectly matched to the belt and pulley, the efficiency of not just the belt drive but the entire drive train is optimised.

The ideal shaft hub connection for your application

Our shaft-hub connections are characterised by simple assembly and disassembly with conventional tools and simple adjustment.

In contrast to positive shaft-hub connections, where the power is transmitted via the form (e.g. splined shaft connections) or via a driver element (feather key), in the case of force-locking shaft-hub connections, the power transmission is achieved via the frictional connection, which is generated by tensioning the connecting element between the shaft and the hub. Which type of connection is chosen (force-, form- or material-locking) depends on the degree of stress and the torque to be transmitted.

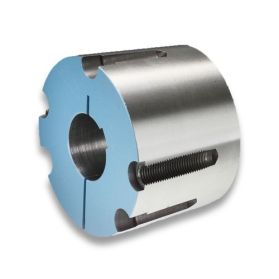

In addition to the comprehensive range of (cylindrical) clamping elements, APSOparts also offers you an extensive range of conical TL-clamping elements, weld-in and screw-on hubs.