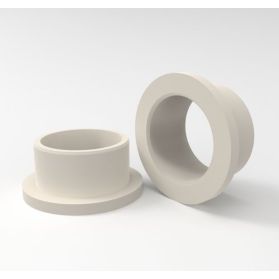

Flanged bearing sleeve APSOplast® PA 66, mod.

Technical data

| Material | polyamide 66 |

|---|---|

| Material additive | 30% glass fibre + 12% PTFE |

| Abbreviated material designation | PA 66 GF30 SL |

| Manufacturing process | injection moulding |

| Color | beige |

| Working temperature range | from -30 to +110 °C |

| Max. operating temperature short term | +130 °C |

| Load specific max., static | 25 N/mm² |

| PV value max. for dry running condition | 0.18 N/mm² · m/s |

| EC Norm | 1907/2006/EU (REACH), 2011/65/EU (RoHS) |

| UNSPSC Code | UNSPSC-31171509 |

| Application |

|---|

| as axial-radial bearing for low wear operation at high load and temperatures e.g.for lever- and hinged bearings, guides and bearing for stroke and rotation with hardened corrugated, also for dry running operations. |

| Version |

|---|

| with flange |

| Attention |

|---|

| backlash-free precision bearing not possible due to the absorption of moisture. |

| On request |

|---|

| in other dimensions; in other plastic materials e.g. POM, PEEK etc. in lathed versions from our Service-Center |

| Assembly |

|---|

| Case boring H7, recommended shaft tolerances h9; for further bearing layouts our plastics specialists are at your disposal. |

| Characteristics |

|---|

| low cost axial-radial bearing with high pressure and wear resistance and high form stability |

9 articles

| Article number | Enter quantity | Availability | Delivery date | Total price | Actions |

|---|